Menu

When measuring the inner diameter (ID) of a curved workpiece, a common mistake occurs when users attempt to use standard vernier calipers. The issue arises because standard jaws are not designed to measure curved surfaces accurately. The simple solution is to switch to a vernier caliper specifically suited for the task

Most of the people may already know of how to use vernier calipers due to it user friendly. So what we are talking today is about the common mistake that many people may make during measuring of Inner Diameter. ID Inner Diameter can be measured with Air Micrometer also

First of all, when the user measure something (In this case is ring-shape type).

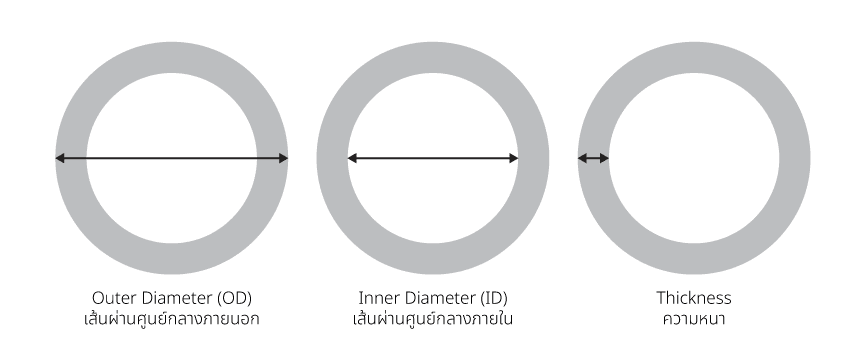

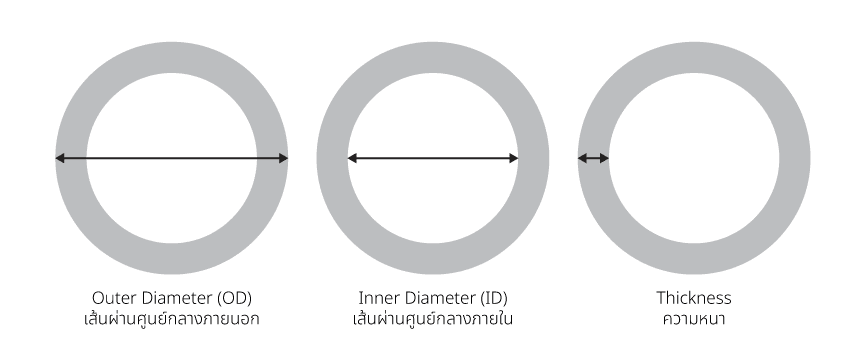

ID knows as Inner Diameter. OD knows as Outer diameter and Thickness of the object.

Trick question: If the object has OD 10mm and thickness 2mm, how much is length of ID?….

8mm? wrong! Don’t forget to minus both side of thickness so ID is 6mm

Start with OD (Outer Diameter); OD starts from the outer part side to side and includes thickness.

OD can be done with any natural means or special technique. It just depends on the selection of Jaw-type to serve the user’s purpose.

** OD measuring can be done with generally tool like Calipers or Air micrometer and with Caliper, user can be using it without any problem with it. There are quite several Jaw-types for OD measuring as well. (Pointy jaw, Offset jaw, Depth type, Blade jaw type, etc.)

When measuring curved parts, problems often arise because square-type jaws may not accurately reach the curvature of the workpiece

Common mistake that user may always overlook at it is within ID (Inner Diameter) measurement. Small part that user overlook (Real small)

Now we can Cleary see it from the diagram above if we use Jaws for measurement Inner Diameter Rediused Jaws. Common objects that use this jaw are object with circle based (Cylinder pipe, Ring, Bearing)

Using Vernier Calipers that suit your purpose is a preferable choice that may result in higher precision.