Menu

RONDCOM NEX: A Roundness tester machine that comes together with the ability to measure surface roughness. RONDCOM NEX is able to measure roundness of workpiece and the roughness of the surface of workpiece.

Raising its own kind of Roundness tester to the next class, the one and only RONDCOM : Solution for roundness tester

AFD (Automatic Force detection), which will detect and prevent Stylus dropping from measuring the workpiece.

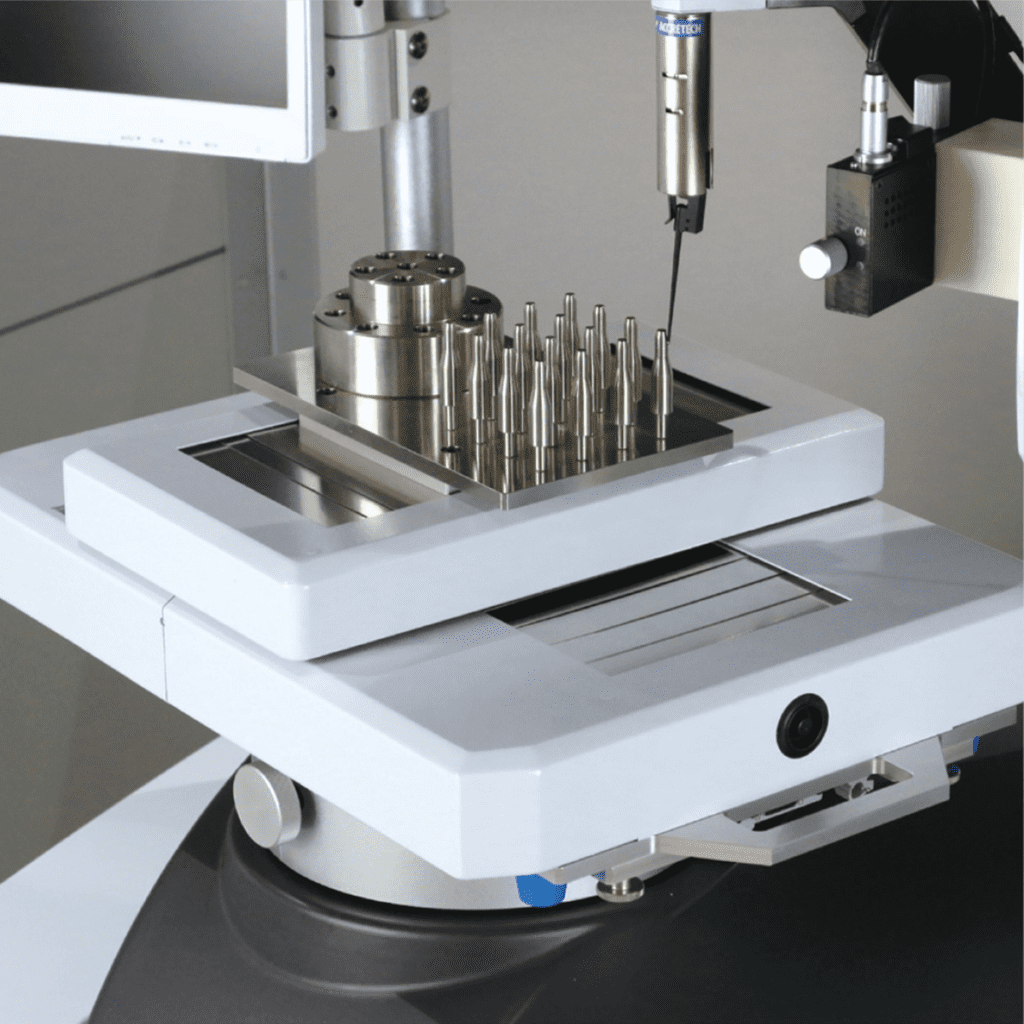

RONDCOM NEX is able to measure many workpieces all together by XY-Axis automatic stage, which will reduce the time consumption in measuring each workpiece

RONDCOM NEX Rs

RONDCOM NEX Rs α

Contact us