Menu

Many people may have knows what is Precision engineering and for those who didn’t know what is Precision engineering.

Precision engineering are the main key player of all the Manufacturing factory. Because when the factory is producing a product and factory need to control the quality within the set standard range to be precise and accurate

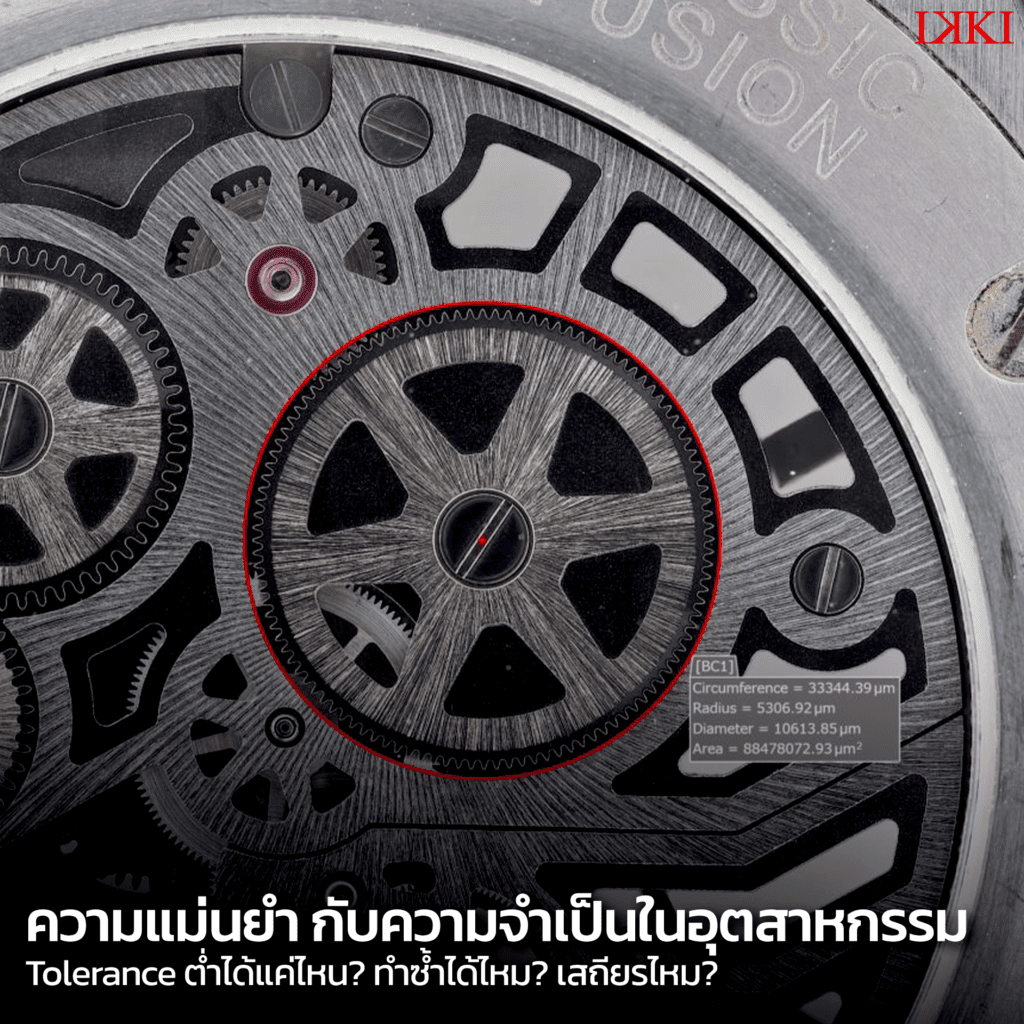

In any industrial field and Quality Process Control, they always have to face the question of… How many Tolerance could you go down? Can you repeat production of this quality? Is it stable production?

Every production and every control that happens in the factory always needs to have the expected precision value, much or less is up to the needs of each part.

For the high efficiency of production and not to exceed the total cost. Some parts may not require high precision, but if we use high-quality tools to measure or too-good materials, it may consume more time and increase the set budget.

To increase precision production and maintain precision level is one of the key to level-up the quality of production.

Never the less, precision engineering can’t be escaped (For those who are going to study precision engineering) from the calculation.

Because every production is required to have calculation and understanding for the prediction before production, during production and other like….

Start with The understanding of material properties

Selecting the measuring and inspecting equipment suit for manufacturing is important too

To inspect the workpiece after produce some part or products by Inspection tool

The Calibration for every tool is also one part of the important key

Apart from the tools, there is one more thing that precision engineering needs to be getting into it is… Monitoring of every produced product by SPC Software and keeping track of Calibration Schedule. If you miss one calibration of the tool, the machine and parts, it would not be the quality level that you expect. Working better and Working Flow smoother may result in better of quality

Therefore, Precision Engineer will be the important position in the any factory which will be part of every process. Before production, during production (Control the workflow during production operation) , quality control and inspecting finished product